sheet metal box bending Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake . Each case has 48 Small Plain Metal Lunch Boxes; Each lunchbox is individually .

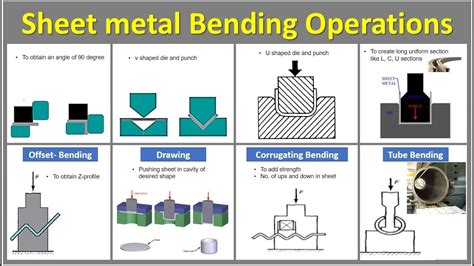

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Shop for Junction Boxes today at MSC Industrial Supply. Our large inventory of Junction Boxes are in stock and ready to ship. Browse from over 600K items!

Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake. .more. Creating a 22 gauge sheetmetal box from scratch.Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake . You can perform various intricate sheet metal operations, such as reinforcing floor channels, corrugated pickup truck beds, truck headboards, metal mudguards, etc., all achievable using this segmented sheet metal brake. Heavy-Duty Metal Sheet Brake: The maximum bending width of the box and pan brake is 24 inches/610 millimeters.

Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When the sheet metal bend is aligned with the direction of the metal fibers, it is more likely to crack at the bend and .Find your professional custom sheet metal box manufacturers here for sheet metal box fabrication. We can control the tolerance between 0.1mm-0.2mm with our advanced technology in customizing metal box made of 316/304 stainless . 1.4 Deep box bending with 30°–60° degree tooling; 2 Got a deeper box? No problem! 3 Sheet Metal Bend Gains Chart. 3.1 BEND GAINS CHART DOWNLOAD; 4 Deep Forming Sheet Metal FAQ. 4.0.1 What challenges do sheet metal fabricators face when forming deep boxes? 4.0.2 How does Approved Sheet Metal address deep forming issues for customers? Springback is defined as a material's natural tendency to return to its unbent position. This is caused by the tension between the material's expansion on the outside of the radius and the compression on the inside (see Figure 4).. Besides the usual springback considerations for a normal bend, the width of the ram needs to be taken into account with .

About this item. Mini Sheet Metal Brake: The maximum bending width of the box and pan brake is 36 inches (910 millimeters). Upgraded with a 0.31-inch thick blade and reinforced rib design, this product achieves excellent bending results, effortlessly handling 20-gauge low-carbon steel and 14-gauge aluminum bending.

types of bending sheet metal

Box bending is a common press brake operation, but it does require forethought with respect to your choice of press brake and tooling. +31 573 289 850 Find your local dealer EN . Bending sheet metal by enclosing the sheet between the punch and the die.How long does it take to bend a sheet metal box. According to data collected by one of our customers, it takes several minutes to bend a sheet metal box of considerable size.The process has an important manual component, generates faulty parts, can cause damage and injury, and takes a long time. A box with rounded edges requires two operators and almost 2 minutes to . Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it.VEVOR Box and Pan Brake, 36-Inch, 0-130 Degrees Sheet Metal Bending Brake, Portable Mini Metal Bender with 20 Gauge Low Carbon Steel 14 Gauge Aluminum Capacity Power Handle, for Metal Bending KASTFORCE KF5006 Box and Pan Brake Sheet Metal Folder Bending Brake Metal Forming Machine Max Capacity 24 Inch (610mm) 20 Ga (1.0mm) with 5 Fingers 0-135 deg

The diagram shows what happens when you bend a piece of sheet metal. The bend allowance is the size of that messy bit in the middle which you need to know. The next diagram shows how a side would unfold, including its bend allowance. So what we need is a piece of metal that is 2 x H, plus W, plus 2 x bend allowance, whatever that is.

sheet metal bending standards

Using the GoPro Hero3 & making videos for education.Box and Pan Metal Brake: A Box and Pan Brake, also known as a finger brake, is a sheet metal bending machine. It uses a clamping bar and removable fingers to precisely fold sheet metal into boxes, pans, and other complex shapes. This versatile tool allows for accurate bending in various materials like stainless steel and aluminum.

The three-axis manipulator bending is mainly used for mass production and relatively simple spatial structure sheet metal products, such as box-shaped parts, slot parts, box parts, etc. Its main advantage is the low investment cost, high efficiency for mass produced parts, but due to the limitations of its spatial running track and poor .

CNC Press Brake Machine, Sheet Metal Bending Machine for bending box, cabinet#bendingmachine #pressbrake #cncpressbrake #electricpressbrake Factory Name:Wuxi. VEVOR Box and Pan Brake, 24-Inch, 0-130 Degrees Sheet Metal Bending Brake, Portable Metal Bender with 20 Gauge Low Carbon Steel 14 Gauge Aluminum Capacity, 5 Adjustable Fingers for Metal Bending .

HUNSONE CNC Press Brake Bending Sheet Metal Box. #hunsone #bending #cncbending #cncbendingmachine #cncbendingpresses #bendingmachine #bendingmetal #precision.The segmented, top beam of box-and-pan brakes allows them to make multiple bends in sheet metal workpieces and form boxes, trays, and pans. Also known as finger brakes, their top beam consists of individual plates (fingers) that can be removed to . Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.

pvc junction box catalogue pdf

Amazon.com: sheet metal bending tool. . 45°, and 90° Metal Bending Pliers with Tool Box Storage Case for Bending and Flattening Sheet Metal. 4.8 out of 5 stars. 37. 50+ bought in past month. .99 $ 49. 99. FREE delivery Sun, Oct 27 . Or fastest delivery Wed, Oct 23 . Seller rating: 4.9/5 (1,157) Add to cart- Pan and Box Brake,24 Inch Sheet Metal Bender,0-135° Bending Precision Solid Construction Sheet Metal Brake with 5 removable Fingers,Industrial Sheet Metal Hand Brake for Shear,Bending,Rolling 1 offer from 500 $ 265 00

Sheet metal boxes are two-part enclosures made by cutting metal sheets and then bending the resulting parts using a press brake to form a box. By adding cutouts for ports, switches, ventilation, or mounting, these versatile and cost-effective enclosures can be used in applications ranging from electronics to robotics.This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Search Now. Popular search terms. . Box Build Assembly; SOLUTIONS. Contract Manufacturing; Assembly; Pipe and Tube Processing; Plastic Injection; Stamping; Sheet Metal Fabrication; Laser Cutting .Ironton Portable Sheet Metal Bending Brake, 30in. Wide. Item # 101452. .99 . Shipping: Available now See Shipping Options. Store Pickup: Check Store Stock. . Baileigh, Heavy Duty Manual Box and Pan Brake, Max. Material Gauge 16 Model# BB-12016. Item # 4685932. ,499.00 . Shipping: Free shipping - Factory shipped See Shipping Options.

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.Amazon.com: sheet metal bending pliers. Skip to main content.us. . 45°, and 90° Metal Bending Pliers with Tool Box Storage Case for Bending and Flattening Sheet Metal. 4.8 out of 5 stars. 30. 50+ bought in past month. .99 $ 49. 99. FREE delivery Wed, Jul 17 . Add to cart-Remove. BOX AND PAN SHEET METAL BRAKE: The Eastwood 48" Pan and Box Sheet Metal Break is a able to make accurate, variable length bends in angles up to 135 degrees in mild, 18 gauge sheet steel and 16 gauge aluminum in widths up to 48 inch. Has 16 removable hardened and ground fingers.

putting an outlet in a junction box

sheet metal bending near me

Explore & source all the CNC replacement parts you need to keep your machine in top working order. Connect with us if you need help finding the correct part.

sheet metal box bending|problems with sheet metal bending